Competition name: Grant funding competition for young scientists under the project "Zhas Galym" for 2024-2026.

Project Manager: Zhanerke T. Toleukhanova, postdoctoral fellow.Specialist in materials science, medical and technical physics.

Identifiers:

- ORCID: 0009-0002-9254-3901 (https://orcid.org/0009-0002-9254-3901).

Project Research Team

| № | Full name | Project position | Identifiers (Scopus Author ID, Researcher ID, ORCID, if any) and links to related profiles |

|---|---|---|---|

|

1. |

Zhanerke T. Toleukhanova |

The scientific director of the project |

ORCID: 0009-0002-9254-3901 (https://orcid.org/0009-0002-9254-3901) |

|

2. |

Didar K. Yeskermessov |

Scientific consultant |

The Hirsch Index in Scopus – 5. |

Project abstract

The chemical element Ti (titanium) and its compounds (nitrides, oxides, various alloys and steels) demonstrate excellent biocompatibility/bioinertness, corrosion resistance and physical and mechanical properties and therefore are widely used in almost all types of orthopedic and dental support devices. Depending on the application, these devices can fulfill a wide variety of functions, from providing temporary structural support to bone repair, long-term joint replacement, filling dental cavities or detecting stimulus changes in the implant area. Orthopedic implants are increasingly being used to partially support or completely replace parts of the human skeletal system that are experiencing problems due to increased longevity, various genetic defects and increased damage from everyday accidents. Therefore, they are expected to have superior mechanical performance for extended life and for service life under daily cyclic use. Poor tribological characteristics, as exemplified by the Ti6Al4V alloy commonly used for these implants, can also lead to the formation of fine wear particles during constant joint movement. These fine particles containing the chemical elements Al (aluminum) and V (vanadium) can cause toxicity to the biological systems surrounding the implant, as well as cause premature loosening of the joint, resulting in a shortened implant life and the need for costly reconstructive surgery.

In addition, medical devices made of stainless steel are prone to corrosion in acidic and chloride-rich environments that are often found in biological systems. This increases the need for careful selection of materials for orthopedic implants to ensure enhanced mechanical hardness, wear resistance, and biocompatibility. It is extremely important that the biomaterials used for manufacturing these implants have the right combination of mechanical, morphological, structural and biomedical properties to prolong their service life in the human body. The chromocobalt alloys and stainless steel used in recent times are practically not used today because of their insufficient resistance to various types of biological media, poor grafting and the risk of causing allergic reactions.

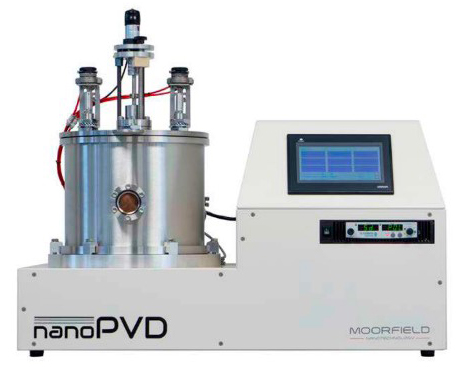

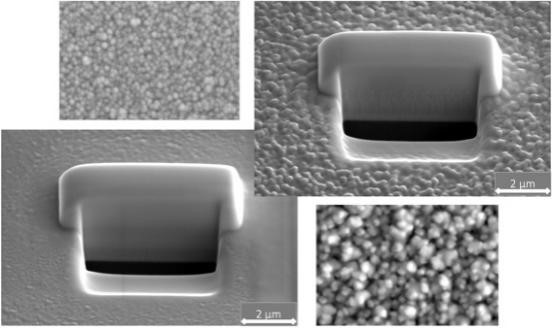

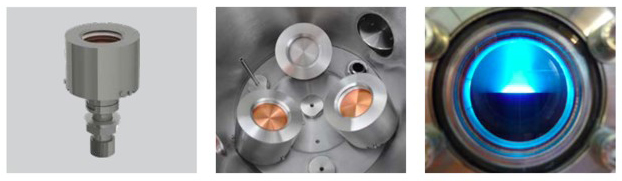

Another highly biocompatible element belonging to the same family as Ag (silver) and Cu (copper) is Au (gold). We assume from the literature search that the alloying of Au with Ti can lead to the intermetallic structure Ti3Au (β-phase), which has extremely high hardness. According to the statistics of published papers in the Scopus database on the study of medical materials coated on the basis of Ti-Au, obtained by various methods, it is possible to notice the relevance of this research direction. The unique method for today is magnetron sputtering (PVD), which allows to obtain very thin with thickness up to 1 micron biocompatible coatings on the basis of Ti-Au with improved physical and mechanical properties on implants of any shape, while the homogeneity over the whole surface is preserved.

The aim of this research is to obtain Ti-Au-based coatings with higher corrosion resistance, better biocompatibility and better physical and mechanical properties than technically pure titanium and its alloys and to study the structural-phase composition, morphology and elemental composition of the obtained coatings. As well as search for optimal voltammetric technological modes and vacuum-inert (Ar+N2/O2) gas compositions for surface modification of the sample with subsequent sputtering in the chamber of the PVD unit.

Expected and achieved results of the project:

1) Development and optimization of new trends and effective technological spraying modes using the experience of researchers in obtaining surface bio-inert Ti-AI Coatings by PVD method;

2) Determination of optimal Volt-Ampere modes, vacuum-gas compositions, preparation and selection of targets based on Ti-Au with the addition of Ag and Cu elements, increasing physical and mechanical characteristics, corrosion resistance and obtaining a bio-inert Ti-AI coating.

| Year |

The results obtained from the research. |

|---|---|

|

2024 |

An article has been published in the Bulletin of the L.N. Gumilyov ENU. Physics and Astronomy Series (№3(148)/ 2024). |

| 2025 | |

| 2026 |

Infographics

Date of last changes:13.01.2026